Bespoke starter motor systems, high-quality flywheels and precision machining since 1968

History

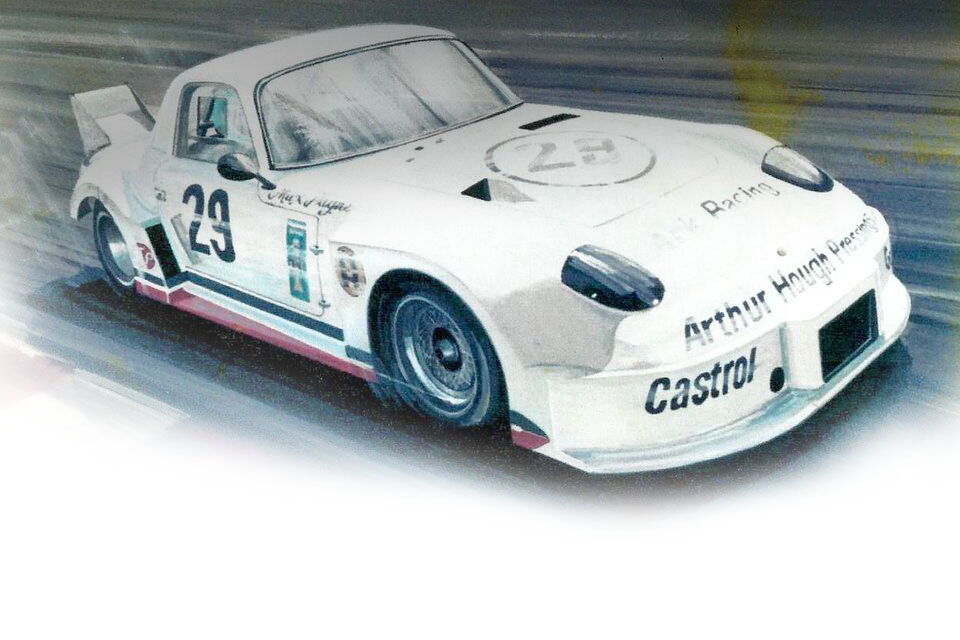

Ark Racing Archives | 1968 - 2004

1968 - Derek Mathews set up a business as Ark Racing in Croft Street, Willenhall. He had already been preparing cars for private individuals to race, and by starting Ark Racing had now secured a workshop in a thriving industrial area.

His initial projects included a Sprite for John Banks. By the end of 1969, his first season, Banks had recorded eleven top three placing from twenty-one outings in his 1300cc Sprite.

Following this success, the racing team turned their attention to overhauling the car, and work began on the ARKSPRITE TWIN-CAM-70L.

After satisfactorily competing in a number of club GT events, Ark entered into its first International event, the 1970Nürburgring 500km race. They finished 2nd in their class. Later that year, they competed in the 6-hour race at Jarama Circuit in Spain, which saw them finish 2nd in class.

In August 1971, the team returned to UK racing and entered the ARKSPRITE into the Birkett Relay 6-hour race. They were victorious. It was the first time in the 21-year history of the Birkett Relay that the winning car had covered more than 500 miles (over 800 km). They collected the Speedwell Cup for the first car to exceed 500 miles. The car competed a number of times following this success and was finally sold.

1970 - Ark Racing had been asked to design a 2-seater sports car. The build had a number of contributors, with Ark making the front suspension, brakes and body. The car made its race debut at Oulton Park in October in the Humble Group Trophy race for GT cars. It succeeded in taking 5th place overall, a class win and the fastest lap for the class.

1974 - The car which was now called the "Vogue" had been upgraded to a 1800cc 4-cylinder, 16-valve Ford Cosworth BDG engine with Lucas injection installed.

1975 - Richard Jenvey, the Bridgnorth Modsports Lotus Elan driver, put together a deal with Lester Ray to drive the car with Derek Matthews continuing the preparation.

From here, the car was successfully raced in the UK and European circuits, progressing through a number of rebuilds.

1977 - Ark Racing left this partnership and moved on to its next project, to build a Lotus Elan to compete in Modsports racing

The Lotus Elan had 17 outings, only once finishing outside the top three in its class on one occasion. In 1975, the Elan won its class and the outright championship of the BRSCC Modsports Series, finishing 2nd in its class behind the overall champion in the BARC Series, achieving outright wins at Mallory Park on three occasions, Silverstone twice and once at Thruxton.

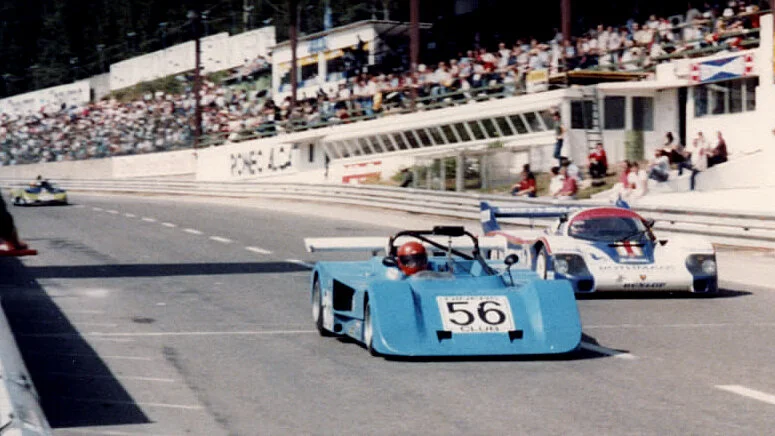

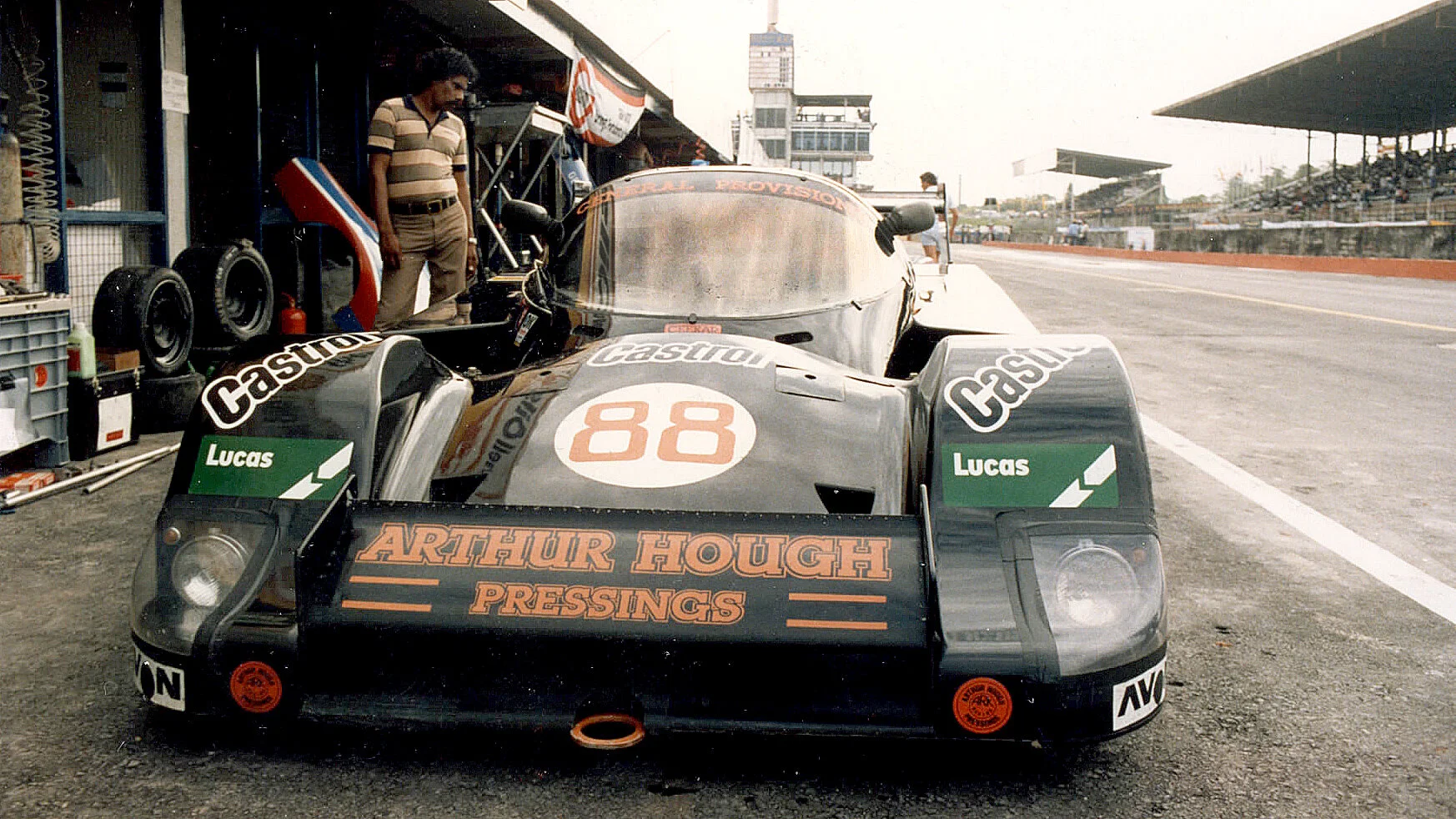

1982 | The CEEKAR

Group C was introduced by FISA on 1 January 1982. The aptly named CEEKAR was built to race in the Group C World Sports Car Championship/World Endurance Championship. The 1985 season had been one of the World Endurance Championships’ fairy tales. The small team of Willenhall's GENTLEMEN DRIVERS set out to take part, rather than to win with the CEEKAR-FORD, and finished up third in the Group C2 Championship of Teams.

Ark Racing continued to design and build components to supply the world of competitive racing. The focus remains on bespoke parts to enable customers to gain a competitive advantage on the start line and in the field. Derek Mathews remained at the helm until his retirement in 2004.

Ark Racing® Limited and New Beginnings | 2003 - Present

(Pictured left) Ark Racing Limited Ark Racing Building, Unit 8-10 Croft Street, Willenhall. (Pictured right) ARKCNC, Unit 11-15 Croft Street.

2003 - Father and son Nick and David Beere purchased Ark Racing in November from Derek Matthews. That year, Ark Racing was incorporated as a ‘Limited company’. Nick Beere, himself a motorsport enthusiast and engineer, had also cut his teeth in competitive racing as a privateer and driver in hill-climbs, sprints and trials. Nick was intent on taking Ark Racing Limited from its niche as ‘the best-kept secret’ in motorsport engineering to a respected leading supplier to Premier Racing Teams.

2004 - The period following 2004 saw many important and exciting changes within the business. The introduction of New Technology, CAD modelling and CNC machinery enabled them to diversify from pure lightweight starter motor manufacture into design and development projects, prototyping, manufacturing flywheels, alternators, clutch systems and fabricated parts for a bewildering range of sports and racing cars, dating from a 1905 Sunbeam to present-day Formula 1, 2 and 3 machinery.

The development of the Ark Racing ‘Off Car Starter’ for Pre-war ERA Racing cars through to GP2 and other series became one of their first unique and leading product ranges.

2006

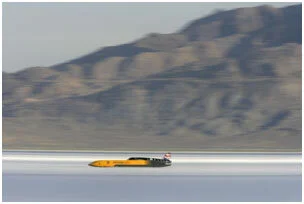

JCB DIESELMAX Bonneville Salt Flats 2006

2006 -Ark Racing Limited supplied special starters for the JCB record-breaking diesel car JCB DieselMax.

The team achieved an average speed of 350.092mph, thereby setting a new FIA diesel land-speed record in 2006 Bonneville Salt Flats during Speed Week.

Interesting and unusual projects have followed, the provision of starter motor systems for Aviation & Marine vehicles, IndyCar, NASCAR and restorations of vintage vehicles. There seems to be nothing that Nick and his team cannot design and build for their customers.

2011 - Ark Racing moved back to its birthplace in Willenhall, West Midlands. The new premises afforded them more space for development projects and the capacity to produce larger quantities of parts. This enabled them to supply and support an entire race series and reduce production times.

2012 - Ark Racing was expanding to supply many leading teams in the motorsport world, including Rally, Road Racing, Historic, Hill climb, Sprint and Endurance Racing.

2015 - Ark Racing exhibited at Cologne Autosport, Germany and had a presence at the IndianapolisAuto Show in 2016. Ark Racing continuously builds up links and friendships with international customers, utilising the full range of web and social media platforms to reach customers around the world.

To complement the company's expanding activities, much of the machinery inherited in 2004 has been superseded by state-of-the-art CNC-controlled Milling and Turning machinery.

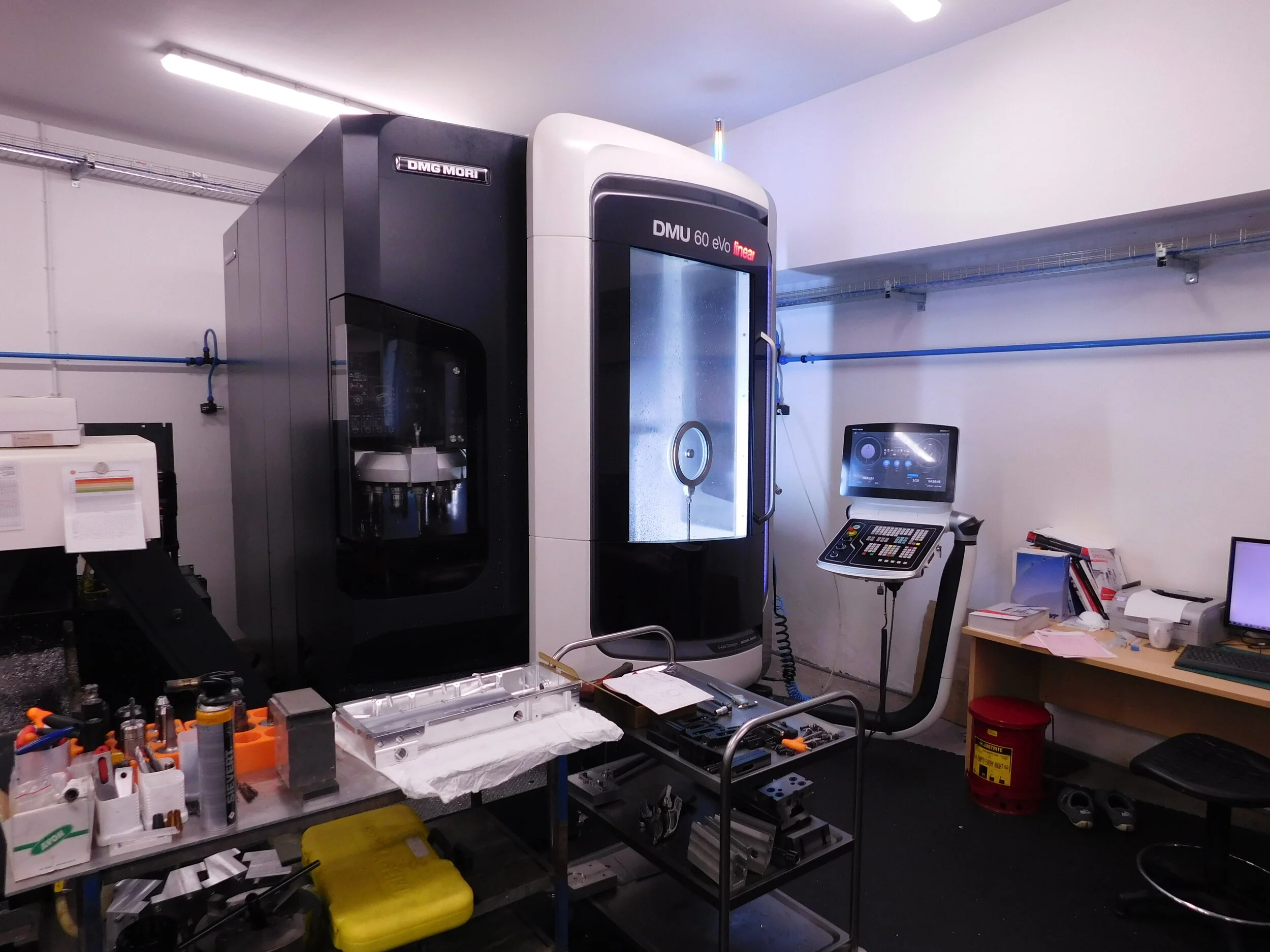

2018 - Ark Racing Limited acquired its first 5-axis milling machine, which has secured its commitment to providing quality products, achieving challenging tolerance and delivering the precise engineering its customers need. This expansion has led Ark Racing Limited to move into general engineering, both within and outside motorsport.

An aluminium Bell Housing being machined by one of Ark Racing 5 Axis machines.

5 Axis cutting edge machining.

The Ark Racing design team fully utilise CAD, Modelling/ Prototyping, 3D printing and design interchange with customers. Developing solutions and supporting customers to move their projects forward through the additional expertise and experience available within Ark Racing. Ark Racing Limited is engaged in Reverse Engineering and heritage projects, looking to recreate tooling and manufacture parts for historic engineering projects.

Ark Racings 3D Printing Service.

Ark Racings Laser Etching Service.

Ark Racings Gasket Cutting Service.

Continuous development on the reliability of Ark Racing’s starter motors and alternator systems has seen major improvements in durability and service intervals. Ark Racing fully supports their product through their servicing team, enabling them to survive life under arduous conditions of Endurance and Rally Motorsport. A starter motor that is regularly serviced by Ark Racing now runs reliably for years.

Whilst others have tried to copy Ark Racing and have fallen short. Ark Racing continues to attract the best professionals in the field of motorsport and mechanical engineering. Its heritage is testimony to its endeavour to offer the best possible service to all its customers, the enthusiast, the privateer and the motorsport team alike.

October 18th 2018. Ark Racing celebrated its 50th anniversary in style with a champagne buffet. See more on our News Feed.

2023 - Ark Racing Limited have Invested in the implementation of Installing Solar Panels, providing a great way to increase our factory’s capacity for renewable energy and possibly save money on energy bills. Whilst providing a greener lower carbon footprint, which is the total amount of greenhouse gases that are emitted into the atmosphere each year by a company, which can contribute to the climate crisis.So where possible we recycle and are doing our part for the planet.

Ark Racing has done it again! Ark Racing, following up with the success of the Triumph T120/140 Electric starter, has successfully released a BSA A65 Electric Starter Kit for distribution via Shropshire Classic Motorcycles.

Ark Racing have also invested in replacement CNC machines for newer efficient models, which are more flexible with improved accuracy and technology.

2024 - April Ark Racing has made more investments in another state-of-the-art DMG-Mori milling machine, this 5-axis precision CNC machine is more than capable of holding the tolerances required for machining modern motorsport components, set in situ on a newly purposed, ultra-level and deep stable concrete base to provide the utmost stability within our Willenhall factory, this will complement our line-up of existing CNC workstations and proves our ongoing commitment into providing our client base with only the highest of standards and quality components.

2025 New improvements: Deployment of upgraded component‑cleaning and surface‑preparation infrastructure across the factory floor. The new suite includes NCH Torrent WetBLAST for controlled wet‑abrasive processing, NCH Dry Blast for high‑energy particulate cleaning, and enclosed Blast Wash Cabinets engineered for consistent, repeatable part cleanliness. Together, these systems enhance surface preparation quality, reduce cycle times, and improve reliability in downstream machining and assembly.

2026 - Upgraded our coordinate measuring capability with the latest Axiom‑series CMM, providing enhanced volumetric accuracy, improved probing repeatability, and greater measurement stability across complex geometries. The new system increases confidence in dimensional verification, supports tighter tolerances, and strengthens overall process capability.

DMU 50 Third Generation